| can't see the pictures? view it in your browser here. | ||||||||||||||||||||||||

|

||||||||||||||||||||||||

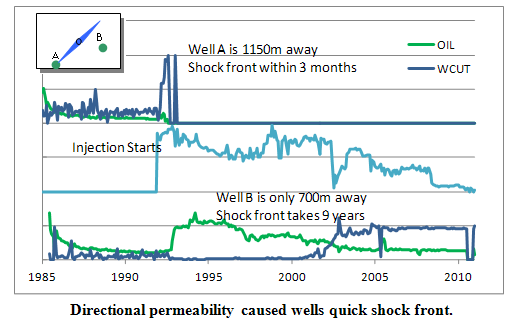

Oil and gas operators are finding that their floods can be much more effective at increasing recovery if they design with directional permeability in mind. Whether you’re injecting water, polymer, or gas, directional permeability can harm or help your flood. Pools with directional permeability preferentially flow in one direction. Permeability along the preferential axis can be 1000 times the permeability orthogonal to that axis. Directional permeability can be caused by several factors including fractures, faults and facies. Many areas of the Pembina Cardium also have strong directional permeability trends. These will significantly impact the use of multi-frac horizontal wells in flooding. Most pools in Alberta exhibit some directional permeability. For example, the Loon Slave Point G Pool in northern Alberta has such significant directional permeability that wells on trend water out almost immediately, but wells off-trend take years to see a water shock front.

In the pattern displayed in the accompanying illustration, Well A was on preferred permeability trend with the injector. This well watered out within 3 months even though it was almost ¾ of a mile away. On the other hand, Well B was less than a half mile away but didn’t see a shock front for 9 years – it was off the preferential permeability trend. After injection, Well B’s oil rate increased six-fold due to the support of the water. By taking advantage of the directional permeability trend, the operator of the flood has experienced a three-fold increase in recovery. Primary recovery factor for the pool was 5%. After the operator decided to use the directional permeability trend, secondary recover factor jumped to 15%. ~Granger J. Low |

|

|

Janet is an engineer in charge of several well projects in Alberta. For a long time, she applied to the board more-or-less “blind” – she applied for what she needed, but wasn’t sure if it was more or less than the board was willing to grant. She often felt grounded in her efforts to maximise her well’s potential. Then she discovered AppIntel, a database tool that gave her instant access to what her competitors were doing offsetting and nearby her well. Suddenly, she could see what other producers were applying for, and what the board was granting in her area. Not only that, but AppIntel also alerted her via email whenever there was a new application submitted or approved near her, so she could keep up to date on developments near her project. This new insight gave her the freedom to apply for – and obtain – the maximum potential for her well. Now, with newfound wings, Janet soars above her project areas, scoping out who is applying for what, and how to get the maximum allowance for her wells. Get the Maximum Approval for your Wells! |

Connie Low is Proven Reserves’ Human Resources Manager having joined Proven’s team over 10 years ago. Connie was born and raised in a small town in Southern Alberta where her father worked as a rancher and political activist. Connie graduated from Brigham Young University with a Bachelor of Science in Education, and minored in Music. She worked as an Elementary School teacher until the birth of her third child, at which time she retired to teach piano privately. Connie remains active in the community and involves herself with her children’s schools and various church activities. In her spare time Connie enjoys travelling to new places and anything to do with music. She participates in various musical projects including musical theatre, a singing trio, and various solo efforts. Thanks Connie! |

|

|

|